We dispense microdropletswith or without contact

Customised micro dispensing"made in Germany"

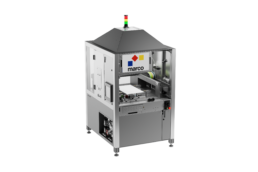

marco System Analysis and Development is at the forefront of manufacturing precision high performance dispensing systems. Our products are critical for the use of a variety of media such as silicone, hot melt and UV adhesives, paints and varnishes, lubricants, solder pastes and fluxes, all of which are precisely dispensed in micro quantities.

We are known for our innovative dispensing valves for contact and non-contact dispensing.

With highly developed piezo valves for unique precision, a variety of customized sealing seats, innovative material preparation systems for mixing or degassing and gantry robots, we play an important role in improving manufacturing processes in almost all industries worldwide.

Components in a marco dispensing system

Precision through understanding

High-precision dispensing requires more than just excellent technology – it demands a deep understanding of your processes. This is where we come in: marco System Analysis and Development GmbH doesn’t just develop dispensing systems – we create the best solution for your specific manufacturing system.

Our high-tech dispensing systems enable the precise application of a wide range of media – from silicones, hot melts, and UV adhesives to paints, coatings, lubricants, solder pastes, and fluxes. And we go a step further, working closely with you to analyse your entire system until we have a deep understanding that enables us to develop the optimum precision dispensing solution for your application.

System Analysis & Development – the key to perfect dispensing

Once we have this in-depth knowledge of your system, we dive deep into your processes. In close collaboration with your engineering team, we analyse the relationships between material properties, application methods, process parameters, and the production environment. This results in a solution precisely tailored to your requirements – whether it’s a high-precision dispensing system, a customised valve design, or an extension of your existing process.

Missing a crucial module to complete your dispensing or production process? We’ll develop it for you. Our name is our promise: System Analysis and Development.

Micro dispensing - precision that makes the difference

Precision is our standard. With our piezo valves for contactless and non-contact dispensing, high-precision valve seats, material preparation systems for mixing or degassing, and intelligent gantry systems, we optimise your processes down to the last detail. The result: maximum dispensing accuracy, less waste, and peak efficiency.

Whether you want to improve an existing system or develop an entirely new dispensing solution – we will support you every step of the way. Because true precision starts with understanding your requirements.

Let’s find the perfect solution for your dispensing application together.

StrongPartnerships

Our partnerships with leading high-tech companies are the key to continuous innovation in microdispensing.

By working closely with our partners, we develop customized solutions that are precisely tailored to the specific requirements and needs of each industry and each customer. This results in dispensing technologies that meet both current and future requirements.

Intensive exchange and our tireless commitment ensure that our customers benefit from the latest developments and dispensing technologies. The result: more efficient processes, higher quality standards and increased competitiveness.

Thanks to these strong partnerships, we are setting new standards together and actively shaping the future of the industry worldwide.

Our sectors

Are precision and efficiency crucial in your industry? Regardless of whether you work in electronics, medical technology, the automotive industry, consumer electronics or another highly specialized sector - the demands on modern manufacturing processes are high.

At marco, we understand the challenges you face every day. With our modular system, we offer you customized solutions for your individual microdispensing requirements.

Our technologies enable you to reliably and precisely dispense the smallest quantities of liquid - with maximum repeat accuracy. Thanks to the flexibility of our modular systems, we can offer you tailor-made solutions that can be seamlessly integrated into your existing production processes. Benefit from our experience and innovative strength to achieve your production goals more efficiently and increase the quality of your products at the same time.

Discover the many possible applications of microdispensing in your industry and find out how we can help you optimize your processes.

Our applications

New microdispensing technologies are the result of years of research, development and sound experience. marco has contributed significantly to the development of this technology and continues to drive innovation.

With marco solutions, precise microdispensing of a wide range of low to high viscosity liquids becomes a reality. Even complex patterns, difficult-to-access or uneven surfaces and different materials in one dispensing cycle are no obstacle for our systems. Our technologies fit seamlessly into existing production systems and offer maximum flexibility for a wide range of liquids.

Thanks to the modularity of marco systems, our solutions can be found in numerous industries: from smartphone manufacturing, medical technology and precision mechanics to LED production, electronics and semiconductor technology and many more. Where precise dispensing is required, marco sets new standards.

Find out more about our application technology and how it can provide the solution for your dispensing application.