Valvetechnology

Dispensing Valve - Your Solution from marco systems

High-precision dispensing valves

Dispensing valves are special valves designed to deliver or dispense liquids or other viscous substances in precisely defined quantities. These valves are primarily used in industrial processes where precision is critical. Various valve types are available on the market, controlled mechanically, pneumatically, hydraulically, or electrically, depending on the model.

marco systems offers you a wide range of different precision valves, all based on marco systems' own piezo technology. Our product range includes highly developed dispensing valves and valve seats or customized dispensing heads that work either contactless or contact-based. Integrated into our gantry systemsthey impress with their flexibility and precision.

Our customers benefit from:

- increased process reliability,

- improved quality assurance and

- highly cost-efficient manufacturing processes.

Innovative and sustainable: What makes our dosing solutions stand out?

marco systems’ dispensing systems are based on the latest technological developments, including the in-house developed piezo technology called TorqueBlock drive, ensuring consistent and reproducible dispensing accuracy. Additionally, the valves from the SJet series feature an actively regulated stroke control ("StrokeControl"). With this regulation, we can define how far, fast, and strongly the valve plunger is moved. Deviations are automatically compensated, and feedback is sent to the control computer in real time. This ensures consistently stable liquid dispensing for both low- andhigh-viscosity liquids. The result? Superior control and flexibility compared to competitors.

Another highlight is the contactless dispensing technology (jetting), designed specifically for industries requiring high precision without direct contact with the substrate. Contactless dispensing is also very fast, making it an efficient method for increasing production capacity.

Contactless dispensing techniques include:

DotJet dispensing: Precise application of dots or drops, ideal for applications requiring small and exact amounts of material. The dispensed quantity is significantly influenced by the geometry of our sealing seats, which can be individually customized.

StringJet dispensing: This method has the same precision characteristics as the DotJet. However, it is particularly suitable for the contactless dispensing of larger quantities of material.

Spraying and coating: A technique where liquids are sprayed in fine doses onto surfaces, ideal for cavities and conformal coating of large or sensitive areas, such as in display manufacturing.

In addition to contactless dispensing techniques, our dispensing valves also support contact-based fluid dispensing:

NeedleDot dispensing is a precise technique where a needle applies tiny fluid dots, ideal for applications requiring maximum accuracy and minimal material amounts.

NeedleLine dispensing is a needle-based process that applies continuous fluid lines, perfectly suited for uniform and controlled applications along complex contours.

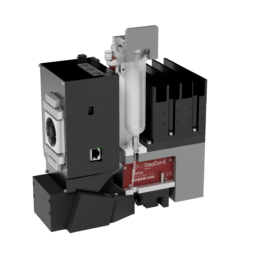

StepDot dosing: An advancement of the NeedleDot and NeedleLine techniques. This dispensing head operates autonomously with independent movement across all spatial axes. Ideal for the precise dispensing of solder paste or the application of dams in the dam-and-fill process.

All our dispensing valves and dispensing heads enable the controlled application of even the smallest quantities, under 1 nL, of adhesives, solder pastes, lubricants, coatings, acrylics, silicones, or 2-component media and more, optimizing production processes and minimizing material waste. This conserves resources and enables sustainable production. At the same time, the modern control technologies of the systems allow energy savings.

An additional advantage: marco systems dispensing solutions can be directly integrated into our own gantry systems (portal robots) if required. This allows our customers to rely on a single, efficient solution instead of coordinating with multiple suppliers. The use of marco systems gantry systems helps companies efficiently increase their production capacity while ensuring the quality of their products.

Industry solutions and applications

marco systems offers dispensing solutions for a wide range of industries. In medical technology, our dispensing valves are used in the production of precision parts that are critical for drug administration. For example, marco systems supplies dispensing heads for the production of nasal sprays and auto-injectors used for precise drug delivery, such as insulin or adrenaline pens. Our high-tech dispensing systems ensure the reliability and quality of the products. In the electronics industry, especially in semiconductor manufacturing or display production, our industrial valves play a crucial role as tiny amounts of solder pastes, fluxes, or silicones must be applied precisely.

In display manufactoring, where microdispensing is used to encapsulate mini LEDs with Liquid Rubber Silicone (LRS), we are a solution partner for major brands. This is where the strength of our systems shines: maximum precision and repeatability ensure the protection and performance of the products.

In the food industry, our dispensing systems contribute to improving packaging processes by optimizing the dispensing of components such as silicone rings or pressure relief valves for packaging.

Technical details and options

At marco systems, you will find a wide range of valves tailored to different requirements. The durable piezo drive of our systems theoretically achieves frequencies of up to 4,000 Hertz and handles over a billion cycles without maintenance.

- Modular Valves SJet: The marco systems SJet technology is characterized by maximum precision and flexibility in dosing.

- Compact Valves: Designed for long-lasting and consistent applications, they are robust due to their minimal design and wear-resistant piezo drive.

- High-viscosity Valves: Extremely powerful dispensing valves with reinforced backs for high-viscosity liquids.

- Tower Valves: Space-saving, offering precise dispensing in a vertical design, ideal for tight working areas.

- BasicValves: Compact, durable precision valves for a wide range of dispensing applications at an attractive price. Offer high dispensing frequencies up to 500 Hz, are easy to handle and compatible with various valve seats and connections.

All our dispensing valves and technologies are easy to integrate into existing production lines and ensure maximum automation and efficiency.

Why choose marco systems dispensing valves?

marco systems dispensing valves have stood for technological expertise and "Made in Germany" quality for decades. All our products undergo rigorous testing and continuous inspections and are ISO 9001 certified. This ensures that the dispensing systems meet the highest standards and operate reliably in sensitive production processes.

Furthermore, we provide our customers with comprehensive support for integrating dispensing systems into existing production lines. From initial consultation and planning to installation and commissioning, the company's experts are at your service. Even after commissioning, customers benefit from a comprehensive service offer that includes regular maintenance and system optimization.

Discover marco systems dispensing valves today

Benefit from precise solutions that not only sustainably optimize your production processes but also significantly enhance the quality of your products. Find out more today. Click on the contact button and send a direct message to our dispensing experts. We will discuss your challenge and develop a customized solution for you.

Headquarters

marco System Analysis and Development GmbH

Hans-Böckler-Strasse 2

85221 Dachau

Germany

Phone: +49 8131 5161-0

Fax: +49 8131 5161-66

info@marco.de