marco Gantry Systems

The marco gantry system series - dosing unit and inline robot: Get a customized complete solution for different applications - all from a single source from marco.Our marc0, marc1 and marc2 gantry systems combine state-of-the-art robot technology with sophisticated dosing control. The lightweight, yet solid design as a tabletop or inline robot always offers the right solution for your needs and location.

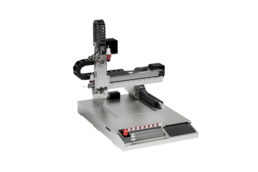

marc0 Gantry System

Features and benefits

- Lightweight, mobile tabletop robot with a working area of 440 x 255 x 140 mm

- For inline or series production in table-top, stand-alone or conveyor belt production

- Continuous position monitoring of the dispensing head by linear encoder

- Thermally stable steel construction ensures the positioning accuracy of the dispensing valve

- Integrated Dispensing Control Unit (DCU) simultaneously controls the robot movements and the dispensing process

Efficient mobility

The marc0 Gantry System has excellent tabletop mobility, weighing only 65kg, the system can be transported and set up with ease.

High-precision tabletop system

The marc0 Gantry System is a versatile, high-precision tabletop system, ideal for various production configurations.

Powerful and precise

The marc0 GantrySystem supports tools weighing up to 1.5 kilograms for high dynamics and 5kg depending on dispensing applications. It accelerates up to 2g in all axes on a large workspace of 440 x 255 x 140mm.

Flexible application options

The machine can be configured for benchtop, stand-alone, or conveyor setups, suitable for both inline and batch processing.

Precise position control

Featuring linear encoders, the system provides closed-loop position control, ensuring constant monitoring of the dispensing tool position.

Unique control unit

The Dispensing Control Unit (DCU) uniquely controls both robot movements and dispensing processes simultaneously, setting itself apart in the industry.

Robust construction

The base is constructed from welded steel housing with materials that share the same coefficient of thermal expansion, maintaining consistent positioning accuracy across varying temperatures.

Consistent accuracy

Thermal stability ensures the metering valve's positioning accuracy remains constant, regardless of extensive temperature changes.

marc1 Gantry System

Features and benefits

- Precise dispensing robot in combination with a dispensing head

- Customized complete solutions from a single source

- High load capacity, lightweight design and very large work surface of 470 x 480 x 120 mm

- Accurate high-speed dispensing with consistent performance, ideal for demanding industrial applications

- Dispenses the smallest quantities of solder paste, silver epoxy or underfill

- Only one control module for dispensing unit and robot

Precise dispensing robot

In combination with the StepDot or other marco piezo valves such as the sJet, the marc1 Gantry System becomes a dispensing robot that follows precise path curves along all axes.

High-precision media dispensing

Capable of dispensing the smallest dots of media such as solder paste, silver epoxy, or underfill, the marc1 GantrySystem ensures accuracy in every application.

Robust and lightweight construction

The marc1 gantry system is characterized by a solid but lightweight design that enables a tool load capacity of up to 13 kg. It offers precise high-speed dispensing with an acceleration of up to 3g while maintaining consistent reproduction. The working area across all axes is 470 x 480 x 120 mm.

Integrated control unit

This system uniquely combines state-of-the-art robot technology with sophisticated dispensing control. The Dispensing Control Unit (DCU) manages both dispensing and motion simultaneously, a standout feature in the industry.

Individual complete solutions

marco offers comprehensive, individualized solutions with the marc1 Gantry System, suitable for various applications. The gantry features a large work surface within a compact footprint.

User-friendly operation

Equipped with a large swivel-mounted HMI touch display and a foldable keyboard, the marc1 Gantry System is designed for easy and intuitive operation.

Reliable high-speed performance

The marc1 Gantry System ensures precise, high-speed dispensing with durable performance, making it ideal for demanding industrial applications.

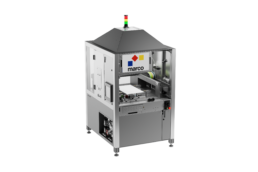

marc2 Gantry System

Features and benefits

- Large work surface of 619 x 940 x 126 mm with a compact footprint and lightweight design

- Dot and line dispensing with high-tech dispensing heads

- Only one DCU to control dispensing and movement

- High tool load with simultaneous high acceleration

- SMEMA-compliant interfaces for integration into a production line

- Modular design with regard to media, air and cooling water supply

- Pre-installed interfaces for integrating additional units and tools

Enhanced precision and versatility

The marc2 Gantry System is a further development of the marc1 Gantry System: it offers the functions of the marc1 Gantry System on a larger footprint.

Improved dispensing capabilities

The marc2 gantry system has been specially developed to precisely dispense the smallest quantities of materials such as solder paste, silver epoxy or underfill in combination with marco high-tech dispensing heads.

Robust and lightweight design

Engineered for precision, the marc2 Gantry System supports tool loads of up to 13 kg, facilitating high-speed dispensing with accelerations of up to 3g and constant repeat accuracy. The working area of the marc2 is 619 x 940 x 126 mm across all axes.

One control unit

The inline robot combines state-of-the-art automation technology with a sophisticated Dispensing Control Unit (DCU) that synchronizes dispensing and motion control, setting a new benchmark in the industry.

User-friendly operation

With the marc2 gantry system, marco offers a complete solution that provides a generous work surface with a compact footprint and lightweight design. The swivel-mounted HMI touch display and foldable keyboard significantly increase user-friendliness.

Modular design

Thanks to its modular design, the marc2 gantry system can be easily adapted to the customer's requirements in terms of media, air and cooling water supply.

Simple configuration

The cell and the machine bed are equipped with numerous pre-installed pneumatic and electronic interfaces that allow additional units and tools to be integrated quickly.

Experience the next level of precision and versatility with the marc2 gantry system, designed for the demanding requirements of modern production environments.

The best thing is to ask marco in person!

With our gantry systems marc0, marc1 and marc2, we offer you a complete solution of dispensing head and inline robot for integration into your production line - all from a single source from marco!

You have requirements - we think your solution. That's where we are strong. Our employees are researchers, tinkerers, developers and fitters. What they all have in common is their enthusiasm for highly specialised plant and mechanical engineering, automation and software development.